U Shape Auto Duct Line V

Products

News

-

How to Maintain a Elbow Duct Machine?

2024-04-08 -

How Does a Duct Seam Closer Work?

2024-03-28 -

Germany Customer Visited

2024-03-13 -

India Customer Visited

2024-03-06 -

20GP container ship to India

2024-03-06

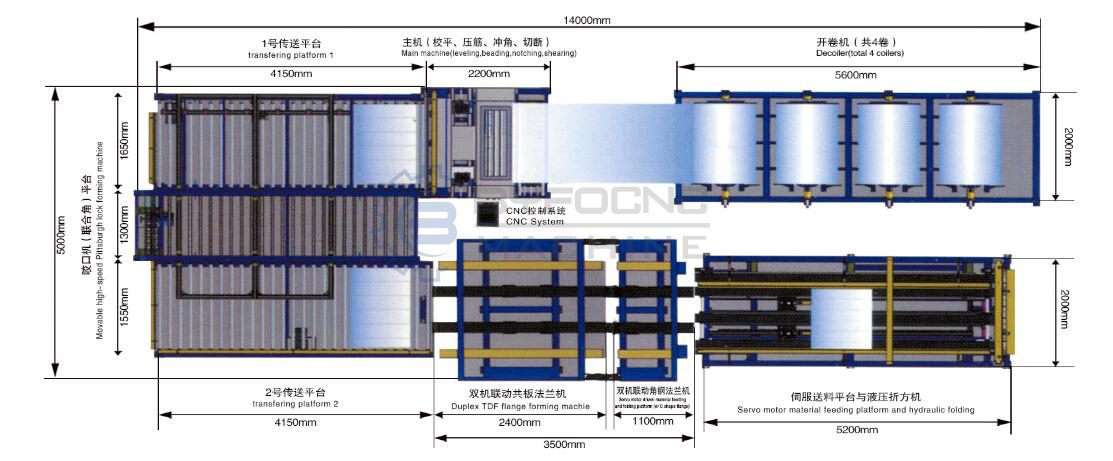

I. Main Features:

Compact U-type structure needs litter space, very suitable for medium-small plant.

Pneumatic mechanical manipulators push plate in conjunction with combined nip machine, high speed and positioning more accurate.

Stepping out from traditional processing method, the nip machine can save a lot of time and significantly improve production efficiency.

Save labor, high efficiency, a piece of L semi-finished product can be finished in 22 min

With production manage function: Day Count, Cumulative Count

Two kinds of input modes (touch screen and keyboard) ensure operation reliability

Optional rod punching, laminating functions

II. Main Functions:

Mainly used for processing TDF flange straight pipe and angle flange ¡°C¡± bone flange, production capacity: 800-2500m2/day

Only need input size, production line could automatically uncoiling, leveling, bending grooving, notching, Pittsburgh lock, TDF flanging forming, angle flange ¡°C¡±bone flange forming, folding square.

Leveling roller is¦µ70 solid roller, made by 45# hardening and tempering steel coated with hard chrome to ensure service life and leveling effect, and protect the metal sheet surface.

Grooving roller is¦µ100 solid roller, made by 45# hardening and tempering steel coated with hard chrome to ensure service life and grooving effect and beauty-appearance.

Conjunction with hydraulic shearing machine whose blade made by 6CrWu2Sisteel, ensures the cutting accuracy ¡À0.5mm without turned edge and burr.

III. Standard Accessories:

Electric uncoiler 1 set (including 4 material trays of 8T)

Support frame

Leveling device

Bending grooving device

Notching Device

Hydraulic shearing machine

1# transmitting platform

Pittsburgh lock machine (combined angle platform)

2# transmitting platform

Tandem TDF flange machine

Tandem angle flange machine

Servo square-folding machine

Controller

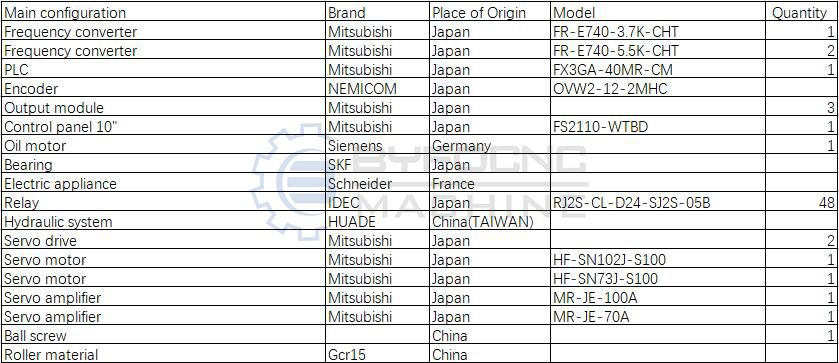

IV. Main Import Configuration:

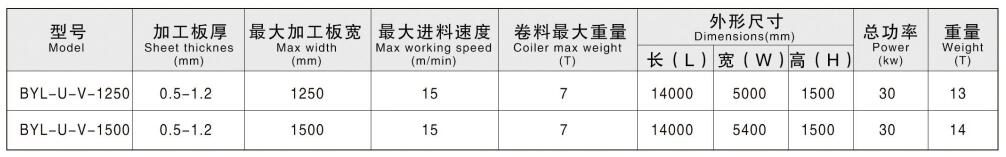

V. Main Technical Parameters

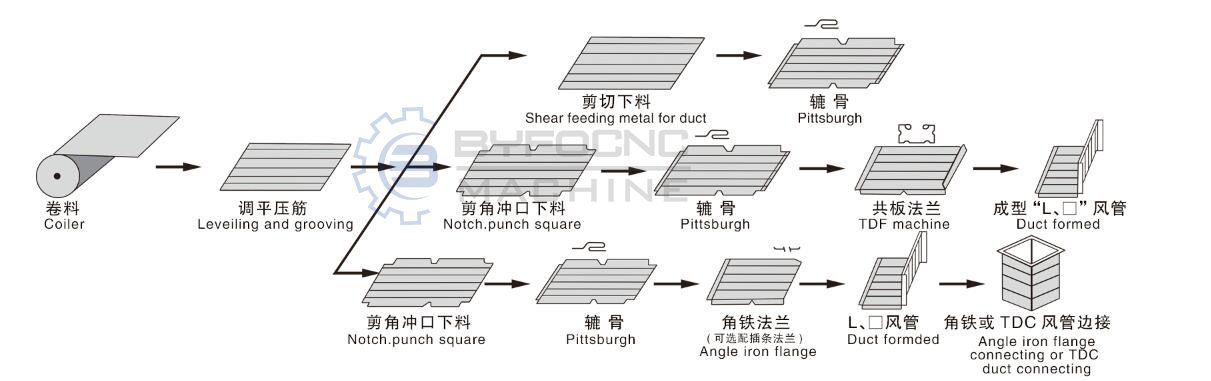

VI. Working Schematic Diagram

VII. Work Flow